Energy-Saving Strategies for Cold Storage Facilities

f you operate a cold storage facility, you already know the brutal truth: your refrigeration systems can account for 60-70% of your total energy costs. For warehouses storing temperature-sensitive products: from pharmaceuticals to produce: keeping temperatures at 0°F or below is non-negotiable. But paying sky-high utility bills doesn't have to be.

Cold storage is one of the most energy-intensive industries in commercial real estate. A single 50,000-square-foot facility can consume more electricity than 500 average homes. The good news? Small operational improvements and strategic energy procurement decisions can slash your costs by 20-40% without compromising product integrity.

At United Energy Consultants, we've worked with cold storage operators across the New York metro area for over 20 years. We've seen firsthand how combining infrastructure upgrades with smart energy buying strategies delivers savings that drop straight to your bottom line. Here's what actually works.

The Cold Storage Energy Challenge: Why Your Bills Are So High

Cold storage facilities face a unique energy dilemma. Unlike typical warehouses, you're running refrigeration equipment 24/7/365. Your compressors, evaporators, and fans never take a break. Add in:

Constant door openings that let in warm, humid air

Thermal bridging through walls and floors

Inefficient legacy equipment from the 1990s still running

Peak demand charges that spike when everyone else is using power

The result? Energy costs that can exceed $1.50 per square foot annually: sometimes double that for deep-freeze operations. But there's a better path forward.

Strategy #1: Building Envelope Improvements That Stop Money from Leaking Out

Your facility's insulation is your first line of defense against energy waste. If heat is constantly infiltrating your cold storage space, your refrigeration systems work overtime to compensate.

Upgrade to high R-value insulation. Modern insulation materials can achieve R-30 to R-50 values, dramatically reducing heat transfer through walls, ceilings, and floors. This is one of the most cost-effective long-term investments you can make. For every dollar spent on premium insulation, you can see $3-5 in energy savings over the system's lifetime.

Seal air leaks relentlessly. Walk your facility with a thermal imaging camera and identify every gap around doors, loading docks, and wall penetrations. Air infiltration is responsible for up to 30% of refrigeration load in poorly sealed facilities.

Install high-speed doors and air curtains. For loading docks and frequently accessed entrances, high-speed doors minimize the time cold air escapes. Pair them with industrial air curtains that create an invisible barrier, maintaining temperature separation while allowing personnel and forklifts to move freely.

Strategy #2: Refrigeration System Optimization

Your compressors are the heartbeat: and the biggest energy drain: of your operation. Upgrading and optimizing refrigeration systems delivers immediate, measurable savings.

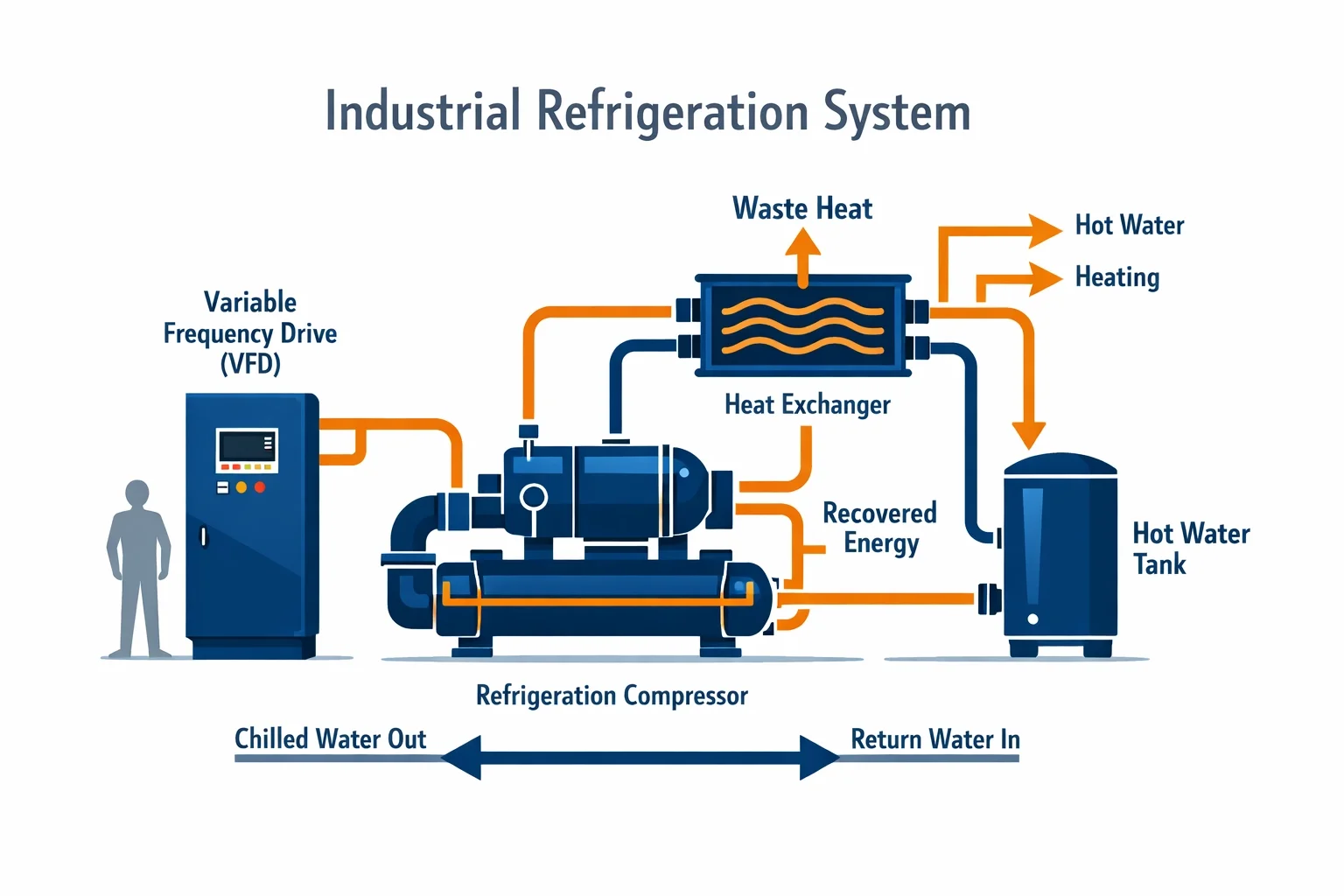

Variable Frequency Drives (VFDs) are game-changers. Traditional compressors run at full capacity regardless of actual cooling demand. VFDs adjust motor speed based on real-time needs, reducing energy consumption by 20-35% during off-peak hours or lower-occupancy periods. If you're running fixed-speed compressors from before 2010, you're leaving serious money on the table.

Switch to low-GWP refrigerants. Transitioning from older refrigerants like R-404A to modern alternatives like CO2 or ammonia improves both efficiency and environmental compliance. CO2 systems can operate at higher efficiency ratios, especially in colder climates where ambient assist reduces load.

Optimize suction and discharge pressures. Most facilities run refrigeration systems at higher pressures than necessary "just to be safe." Work with your HVAC contractor to dial in optimal pressure settings. Every 2°F increase in evaporator temperature can reduce energy use by 1-2%.

Implement heat recovery systems. Your compressors generate enormous amounts of waste heat. Capture it with desuperheaters and repurpose it for facility heating, water heating, or even defrost cycles. This turns waste into an asset.

Strategy #3: Lighting and Controls Upgrades

Lighting might seem minor compared to refrigeration, but in a 100,000-square-foot facility running lights 24/7, it adds up fast.

LED lighting reduces consumption by 60-75%. Modern cold-storage-rated LEDs withstand sub-zero temperatures while delivering better visibility and longer lifespans (50,000+ hours vs. 10,000 for fluorescents). Calculate the payback period: often under 18 months: and make the switch.

Install occupancy sensors and daylighting controls. Why light empty aisles? Motion-activated lighting in low-traffic zones and skylights in offices or receiving areas reduce unnecessary load.

Strategy #4: Smart Monitoring and Predictive Maintenance

Technology is transforming cold storage operations. IoT sensors, real-time monitoring, and AI-powered analytics catch problems before they become expensive failures.

Deploy temperature and humidity sensors throughout your facility. Continuous monitoring prevents overcooling: one of the most common sources of energy waste. If your setpoint is 0°F but you're actually running at -5°F across the warehouse, you're paying for phantom refrigeration.

Use predictive maintenance software. Equipment failures don't just cost you downtime: they spike energy use as backup systems struggle to compensate. Predictive analytics identify compressor inefficiencies, refrigerant leaks, and motor wear before catastrophic failure occurs.

Leverage demand response programs. Utilities like Con Edison offer significant payments to facilities that can briefly reduce load during peak demand events. For cold storage, your thermal mass gives you flexibility: you can reduce refrigeration for 1-2 hours without compromising product safety, earning thousands in annual incentive payments.

Strategy #5: Strategic Energy Procurement: The Hidden Savings Lever

Here's where most cold storage operators leave money on the table: they treat energy as a fixed cost instead of a strategic procurement decision.

In deregulated markets like New York, New Jersey, and Pennsylvania, you can choose your electricity and natural gas supplier. But without expertise and market intelligence, you'll overpay: sometimes by 20-30% compared to what's actually available.

Negotiate wholesale rates, not retail markup. Most cold storage facilities sign contracts with suppliers who add layers of margin. At United Energy Consultants, we leverage relationships with over 80 suppliers to secure wholesale pricing. We're independent: we don't take commissions from suppliers, so we negotiate on your behalf, not theirs.

Time your energy procurement strategically. Energy markets fluctuate. Lock in rates when prices dip, and avoid panic-buying when markets spike. Our team monitors commodity trends daily, so you get the best possible timing on contract renewals.

Implement peak shaving and load management. Demand charges: the fees based on your highest 15-minute energy spike each month: can represent 40-50% of your bill. By shifting non-critical loads (like defrost cycles or administrative HVAC) to off-peak hours and managing your peak demand, you can reduce this charge significantly.

The United Energy Consultants Advantage: Why Independence Matters

We've been helping cold storage facilities and other energy-intensive businesses reduce costs for over 20 years. Here's what sets us apart:

Zero out-of-pocket costs. Our entire service is paid by supplier competition: you pay nothing upfront, and nothing ongoing. We only succeed when you save.

Proprietary Energy Tracker Pro software. Our custom-built platform monitors your usage, tracks contract expiration dates, and alerts you to savings opportunities in real time. You'll never miss a renewal deadline or get auto-rolled into unfavorable rates again.

Over 80 vetted supplier relationships. We put your account out to competitive bid across our entire network, ensuring you get the lowest possible rate with the best contract terms.

Independent, unbiased advice. We don't sell hardware. We don't take commissions from suppliers. We work for you, period. If a supplier is offering a bad deal or locking you into punitive terms, we'll tell you: and walk away from the deal.

20+ years of market expertise. We've navigated multiple energy market cycles, regulatory changes, and price spikes. We know how to structure contracts that protect you in volatile markets.

Small Changes, Massive Savings

Cold storage operations are capital-intensive, but the ROI on energy efficiency and strategic procurement is undeniable. A facility spending $500,000 annually on energy can realistically save $100,000-150,000 per year through a combination of:

Building envelope improvements (10-15% savings)

VFD and equipment upgrades (15-25% savings)

Strategic energy procurement (10-20% savings)

Demand management and peak shaving (5-10% savings)

These aren't theoretical numbers: they're results we've delivered for clients across the tri-state area.

Ready to Stop Overpaying for Energy?

If you operate a cold storage facility and you're not actively managing both your energy consumption and your energy procurement, you're leaving serious money on the table.

Send us a copy of your most recent utility bill. We'll run a free, no-obligation energy audit and show you exactly where you're overpaying and what you can save. No pressure, no sales pitch: just data and a clear path to lower costs.

Contact United Energy Consultants today at www.uecnow.com and let's put those savings back into your business where they belong.

United Energy Consultants – 20+ Years of Independent Energy Expertise in the New York Metro Area